Are you curious about how Tritium, a rare and powerful element, is made? Understanding Tritium manufacturing can open doors to fascinating insights about energy, technology, and innovation.

Whether you’re involved in science, industry, or just want to know more, this guide will break down the process in simple terms. By the end, you’ll see why Tritium plays a key role in modern advancements and how its production impacts your everyday life.

Keep reading to uncover the secrets behind Tritium manufacturing and why it matters to you.

Tritium Basics

Tritium is a rare form of hydrogen. It has one proton and two neutrons. This makes it different from regular hydrogen. Tritium is radioactive and emits low-energy beta particles. It is found naturally in small amounts in the environment.

Tritium is produced in nuclear reactors for many uses. Its unique properties make it useful in science and industry. Understanding tritium helps explain its role in energy and manufacturing.

Properties And Uses

Tritium glows in the dark by itself. It produces light without electricity or batteries. This property makes it useful in emergency exit signs and watch dials. Tritium is also used as a tracer in environmental studies. Its radioactive nature helps track chemical and biological processes.

Because tritium is rare and radioactive, it requires careful handling. It has a half-life of about 12 years. This limits its use and storage time. Despite this, tritium remains important in many scientific fields.

Role In Energy

Tritium plays a key role in nuclear fusion research. Fusion aims to produce clean and abundant energy. Tritium combines with deuterium to create energy in fusion reactors. This reaction releases large amounts of energy with little waste.

Scientists study tritium to improve fusion reactor designs. It helps develop safer and more efficient energy sources. Tritium could be part of future clean energy solutions.

Current Manufacturing Methods

Tritium is a rare and valuable isotope used in many industries. Its manufacturing requires careful methods. These methods ensure tritium meets safety and quality standards. Understanding current manufacturing methods helps us see how tritium is produced today. Two main methods stand out: production in nuclear reactors and extraction techniques.

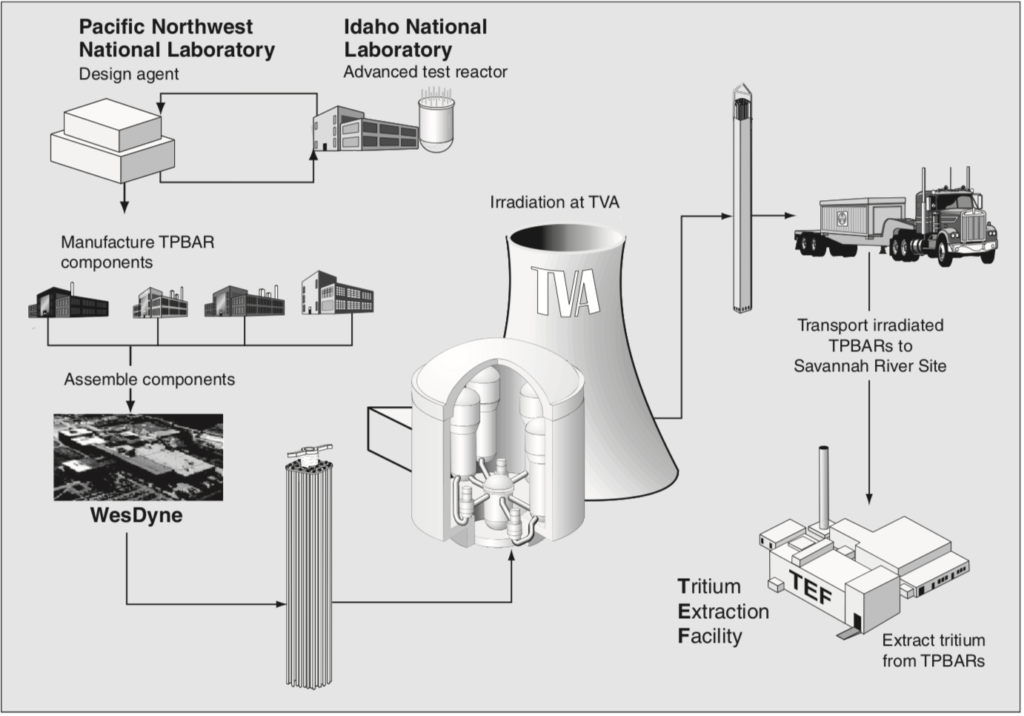

Production In Nuclear Reactors

Nuclear reactors produce tritium by bombarding lithium or heavy water with neutrons. This process creates tritium atoms inside the reactor. The reactors used are usually heavy water reactors or specialized research reactors. The tritium generated is trapped in the reactor’s moderator or target material. This method provides a steady supply of tritium but requires complex equipment and strict controls. Safety measures are critical due to the radioactive nature of the material.

Extraction Techniques

After production, tritium must be extracted from the reactor materials. Extraction involves chemical and physical processes to separate tritium gas from other substances. One common technique is using cryogenic distillation to isolate tritium from hydrogen isotopes. Another method is metal hydride absorption, which selectively traps tritium. These extraction techniques ensure the tritium is pure and ready for use. Proper handling during extraction is vital to prevent leaks and contamination.

Innovative Production Technologies

Innovative production technologies are crucial in the manufacturing of tritium. These methods improve efficiency and safety. They also help meet the growing demand for this rare isotope. Manufacturers use new techniques to produce tritium more reliably and sustainably. Understanding these technologies offers insight into how tritium supports energy and scientific research.

Advanced Fusion Reactors

Advanced fusion reactors play a key role in tritium production. These reactors create high-energy environments to produce tritium from lithium. The process uses nuclear fusion reactions similar to the sun’s energy. Fusion reactors offer a cleaner way to produce tritium. They also reduce radioactive waste compared to older methods. This technology is still developing but shows strong potential for future supply.

Accelerator-based Methods

Accelerator-based methods use particle accelerators to produce tritium. These machines bombard target materials with high-energy particles. The collision creates tritium atoms through nuclear reactions. This method allows precise control over tritium production. It also reduces the risk of contamination and environmental impact. Accelerator-based production is becoming more popular for research and industrial uses.

Materials And Equipment Advances

Advances in materials and equipment have greatly improved tritium manufacturing. New technologies help handle tritium safely and efficiently. These improvements reduce risks and increase production quality.

Better materials resist tritium’s radioactive nature. Updated equipment designs protect workers and the environment. These changes are essential for modern tritium production.

Improved Tritium Handling

Modern tools now handle tritium more safely than before. Special gloves and containers prevent leaks and contamination. Automation reduces human contact with tritium gas. Sensors detect any tritium escape immediately. These steps lower the chance of accidents.

Storage Solutions

New storage methods keep tritium secure for longer times. Advanced tanks use materials that stop tritium from escaping. These tanks control pressure and temperature precisely. Storage units also have better shielding to block radiation. Safe storage protects workers and the environment.

Environmental And Safety Aspects

Tritium manufacturing involves handling radioactive material. This makes environmental and safety aspects very important. Companies must follow strict rules to protect workers and the environment. Safety practices help prevent accidents and reduce harmful effects. Managing radiation and waste is key to safe production.

Radiation Management

Radiation from tritium can harm people and nature. Facilities use shields and barriers to control exposure. Workers wear protective clothing and use monitoring devices. Regular checks ensure radiation levels stay within safe limits. Training helps staff understand risks and follow safety steps. Proper ventilation systems reduce airborne tritium. This limits radiation spread inside the plant.

Waste Reduction Strategies

Tritium waste must be handled carefully to avoid pollution. Companies use methods to reduce the amount of waste produced. Recycling and reusing materials lower environmental impact. Safe storage containers prevent leaks and contamination. Waste is tracked from creation to disposal. This ensures no harmful release into air, water, or soil. Reducing waste saves resources and helps protect nature.

Economic Impact

Tritium manufacturing plays a key role in the economy of many industries. It affects jobs, costs, and market growth. Understanding its economic impact helps businesses and governments make smart choices.

This section explores how tritium manufacturing improves cost efficiency and responds to market demand trends.

Cost Efficiency Improvements

New methods in tritium manufacturing reduce production costs significantly. Efficient processes use less energy and materials. This leads to lower prices for end products. Companies save money, which can fund more research or lower product costs. These savings benefit consumers and boost industry growth.

Market Demand Trends

Demand for tritium is rising in several sectors. It is essential for nuclear power, medical devices, and safety equipment. More countries invest in tritium technology to meet energy and health needs. This demand creates jobs and encourages innovation. It also supports related industries, strengthening the overall market.

Future Energy Applications

Tritium has a key role in the future of energy. Its unique properties make it valuable for new technologies. Scientists and engineers are exploring many ways to use tritium for cleaner energy. These uses could reduce pollution and help meet growing energy needs.

Understanding tritium’s potential helps us see how energy might change soon. Let’s explore some important applications where tritium could make a big impact.

Fusion Power Potential

Tritium is vital for fusion energy, a powerful energy source. Fusion combines light atoms to create heat and energy. It mimics the sun’s energy process. Tritium fuels this reaction efficiently and safely. Fusion power could provide vast energy with little waste. Many labs focus on tritium to improve fusion reactors. Success here means clean, almost unlimited energy for the future.

Other Emerging Uses

Tritium is also used in new energy storage systems. It can help create batteries that last longer. Some research looks at tritium in sensors for energy monitoring. These sensors improve safety and efficiency in power plants. Tritium’s glow helps in low-light displays without electricity. This makes it useful in emergency signs and instruments. These uses show tritium’s broad potential beyond fusion energy.

Frequently Asked Questions

What Is Tritium Manufacturing?

Tritium manufacturing involves producing tritium, a radioactive hydrogen isotope. It is mainly created in nuclear reactors by irradiating lithium or heavy water.

How Is Tritium Used In Industry?

Tritium is used in self-luminous devices, nuclear fusion research, and radioluminescent lighting. It provides safe, long-lasting illumination without electricity.

What Safety Measures Exist In Tritium Production?

Strict containment and monitoring protocols ensure worker safety. Tritium’s radioactivity requires controlled environments to prevent environmental contamination during manufacturing.

Why Is Tritium Important For Nuclear Fusion?

Tritium serves as a key fuel in nuclear fusion reactions. It releases high energy when fused with deuterium, aiding clean energy development.

Conclusion

Tritium manufacturing plays a key role in many industries today. It helps create safe, reliable products used worldwide. Understanding its process sheds light on its importance and challenges. Advances continue to improve production methods and safety measures. This keeps tritium available for energy, medical, and research uses.

The future looks promising with ongoing innovation in this field. Tritium remains a vital resource for science and technology progress.

Apply for this vacancy

For more information

For more information, please don’t hesitate to contact us. We’re here to assist with any questions or provide additional details to help you make informed decisions. Reach out today, and let’s connect!

Please mention the respective article number.

For more information

For more information, please don’t hesitate to contact us. We’re here to assist with any questions or provide additional details to help you make informed decisions. Reach out today, and let’s connect!

Please mention the respective article number.